A supply chain control tower is a centralised platform that provides real-time data and analytics to help companies manage their supply chains. It gives managers a complete view of the supply chain and makes informed decisions that can improve efficiency and optimise costs.

Supply chain control towers are software that helps businesses manage their supply chains. There are many different types of supply chain control towers, each with its unique features and benefits. Your business’s right supply chain control tower will depend on your specific needs and goals. However, all supply chain control towers can help you improve the efficiency and visibility of your supply chain.

This blog post will dive deeply into the supply chain control tower and give you detailed insight.

Supply Chain Control Tower: What Is It? Explain

A supply chain control tower (SCCT) is a platform that uses data analytics and visualisations to give companies real-time visibility into their supply chains. The goal of an SCCT is to help organisations optimise their supply chains by providing them with the information they need to make better decisions.

An SCCT gathers data from multiple sources, including sensors, enterprise resource planning (ERP) systems, and transportation management systems. This data is then processed and analysed to provide information regarding the current state of the supply chain. The SCCT platform also includes collaboration tools so different teams within an organisation can work together to improve the supply chain.

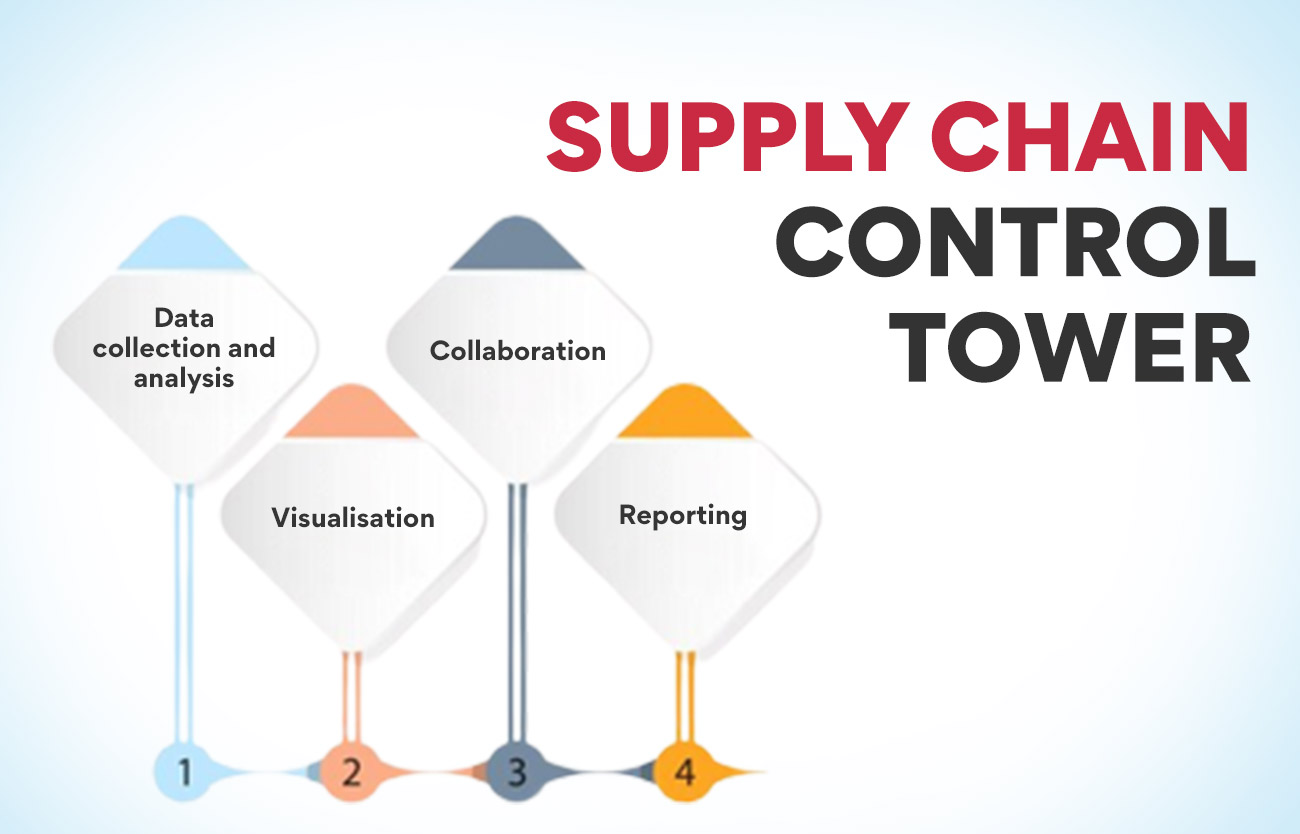

There are many different types of SCCTs, but all share the same goal of helping organisations improve their supply chain management. Some common features of SCCTs include the following:

Data collection and analysis: As mentioned above, one of the key functions of an SCCT is collecting data from various sources and using that data to generate insights into the current state of the supply chain. This data can be used to identify areas of improvement, such as bottlenecks or delays.

Visualisation: Another common feature of SCCTs is visualisation tools that help users understand the data and make better decisions. These tools can take many forms, such as charts, graphs, or heat maps.

Collaboration: As mentioned earlier, collaboration is another essential feature of SCCTs. This feature allows different teams within an organisation to work together on supply chain management.

Reporting: SCCTs also typically include reporting features that allow users to generate reports on the current state of the supply chain. These reports can be used to track progress or share information with other stakeholders.

What Is The Significance of a Supply Chain Control Tower?

In a rapidly changing business landscape, the ability to have visibility and control over your supply chain has become increasingly important. A supply chain control tower is a centralised platform that leverages data and analytics to offer updated and real-time visibility into the extended supply chain. It allows organisations to identify and manage risks proactively, optimise performance, and improve agility.

The benefits of a supply chain control tower are vast and can depend on an organisation’s specific needs. In general, a well-run control tower can help increase efficiency, decrease costs, and enhance customer satisfaction. Additionally, a control tower can improve supplier relationships, better inventory management, and reduce lead times.

When implemented correctly, a supply chain control tower can be a powerful tool for any organisation looking to optimise its operations.

How Does Supply Chain Control Tower Work?

The control tower can track shipments, optimise routes, and monitor inventory levels. It can also be used to identify potential issues and disruptions in the supply chain.

The supply chain control tower is typically operated by a team of analysts who use data from multiple sources to provide insights into the supply chain. The analysts work closely with the company’s operations team to ensure that the supply chain runs smoothly.

The control tower has become an essential tool for companies that rely on complex supply chains. It provides the visibility and insights needed to manage the supply chain effectively.

The control tower concept was first introduced by logistics service providers (LSPs) to manage their client’s freight shipments. However, the term “supply chain control tower” has since been adopted by many companies across different industries to describe their centralised decision platform.

A typical supply chain control tower includes four main components: data management, business intelligence & analytics, performance management, and actionable insights. Data management is responsible for collecting and storing data from various sources across the supply chain. Business intelligence & analytics is responsible for analysing this data to identify trends and patterns. Performance management is responsible for tracking KPIs and setting targets. Actionable insights are generated based on all of this information to make recommendations on improving the supply chain.

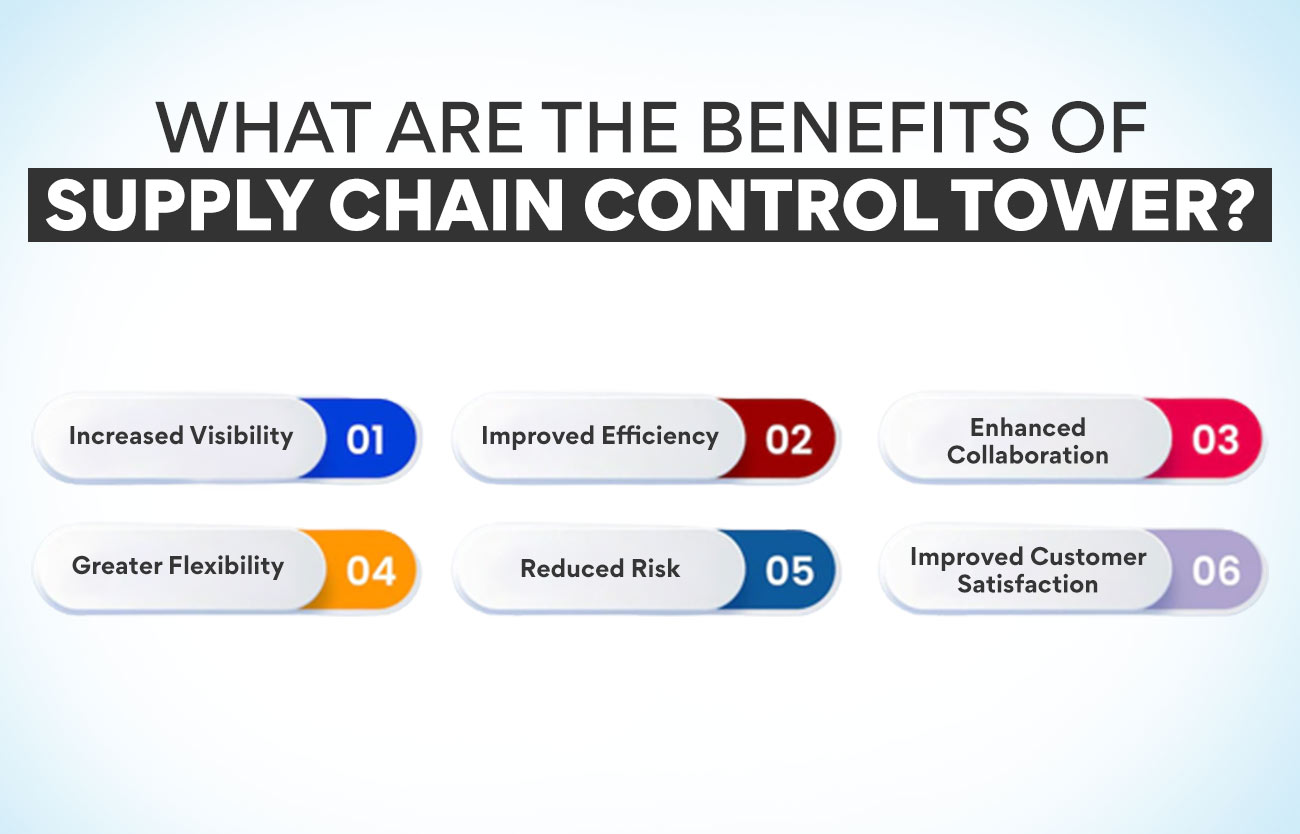

What Are The Benefits of Supply Chain Control Tower?

Increased Visibility

A supply chain control tower provides increased visibility into the supply chain, allowing for better control and management. This visibility can help identify issues and potential problems early on before they cause significant disruptions.

Improved Efficiency

By increasing visibility and traceability throughout the supply chain, a control tower can help to improve efficiency and optimise operations. It can lead to cost savings and performance improvements.

Enhanced Collaboration

A supply chain control tower can also facilitate enhanced collaboration between different stakeholders in the supply chain. Providing a centralised platform for information sharing and communication can help improve coordination and reduce delays.

Greater Flexibility

Another benefit of a supply chain control tower is that it can provide greater flexibility to adapt to changing needs or conditions. This flexibility can be significant in dynamic or uncertain environments.

Reduced Risk

With better visibility and control over the supply chain, a control tower can help to reduce risk throughout the system. It can minimise disruptions and ensure smoother operations overall.

Improved Customer Satisfaction

Finally, a control tower can ultimately lead to improved customer satisfaction by providing a more efficient and reliable supply chain. This happens because customers will receive their orders more quickly and with fewer errors or delays.

Also Read: What is Green Supply Chain? An Overview

What Are The Different Uses of Supply Chain Control Tower?

A supply chain control tower is a centralised platform that uses data and analytics to provide better reach to every aspect of the supply chain. It enables real-time decision-making, collaboration, and communication across the entire supply chain.

The main use of a supply chain control tower is to optimise the flow of goods and information throughout the supply chain. It includes managing inventory levels, tracking shipments, and coordinating transportation. A control tower can also monitor supplier performance, track customer orders, and forecast demand.

Another common use for a supply tower is identifying and managing risk across the supply chain. It includes identifying potential disruptions, such as supplier shortages or natural disasters, and developing contingency plans to avoid or mitigate these disruptions.

In addition to these uses, many companies are now using supply chain control towers to drive digital transformation initiatives. It includes using the platform to connect siloed data sources, enable automated decision-making, and develop new capabilities such as predictive analytics and machine learning.

Different Types of Supply Chain Control Towers

There are different types of supply chain control towers, each with its own set of features and capabilities. Each control tower type has its advantages and disadvantages, so it’s important to pick the suitable one according to your needs. Selecting the right SCCT depends on various factors that influence a business model.

Logistic Control Towers – Explain with Examples

A logistic control tower (LCT) is a centralised unit that uses digital technologies to oversee and coordinate the flow of goods throughout the supply chain. An LCT aims to optimise the movement of goods to improve efficiency and reduce costs.

An LCT can be used to monitor and track shipments, identify issues and delays, and manage inventory levels. It creates transparency across the supply chain so that all stakeholders can see where goods are at any given time.

There are many benefits of using an LCT, including the following:

- Improved coordination and communication between different parts of the supply chain

- Increased visibility of shipments and inventory levels

- Faster identification and resolution of issues

- Reduced costs through improved efficiencies

Examples of companies that have implemented an LCT include Coca-Cola, IBM, Nestlé, Procter & Gamble, and Unilever.

Operational Control Towers – Explain with Examples

Operational control towers are one of the essential components of an organisation. They provide a centralised location from which all operations can be monitored and controlled. Operational control towers can be found in many industries, including manufacturing, healthcare, logistics, and retail.

Operational control towers are typically staffed by a team of professionals responsible for overseeing all aspects of the organisation’s operations. This team may include managers, analysts, engineers, and other specialists. The control tower concept is based on “divide and conquer.” By dividing the organisation’s operations into smaller units, each unit can be more effectively monitored and controlled.

An operational control tower’s most important function is ensuring that all operations are running smoothly. To do this, the control tower team must clearly understand the organisation’s overall goals and objectives. They must also be able to identify potential problems and correct them before they cause major disruptions.

There are different types of control towers, but they all share the same goal of providing visibility into the supply chain. Some common types of operational control towers include:

- Operational Control Towers: These towers focus on optimising day-to-day operations within the supply chain. For example, an operational control tower might be used to track inventory levels in real-time so that reordering can be triggered when supplies start to run low.

- Strategic Control Towers: These towers take a longer-term view of the supply chain and focus on issues such as capacity planning and supplier management. For example, a strategic control tower might be used to develop plans for responding to unexpected demand spikes.

- Financial Control Towers: These towers focus on financial aspects of the supply chain, such as cost management and revenue optimisation. For example, a financial control tower might be used to track spending across different parts of the supply chain so that areas where costs are high, can be identified and addressed.

H2 – Transportation Control Towers – Explain with Examples

A supply chain control tower is a platform that uses data and analytics to provide visibility into all aspects of the supply chain. This visibility enables organisations to make real-time decisions to boost performance and optimise costs.

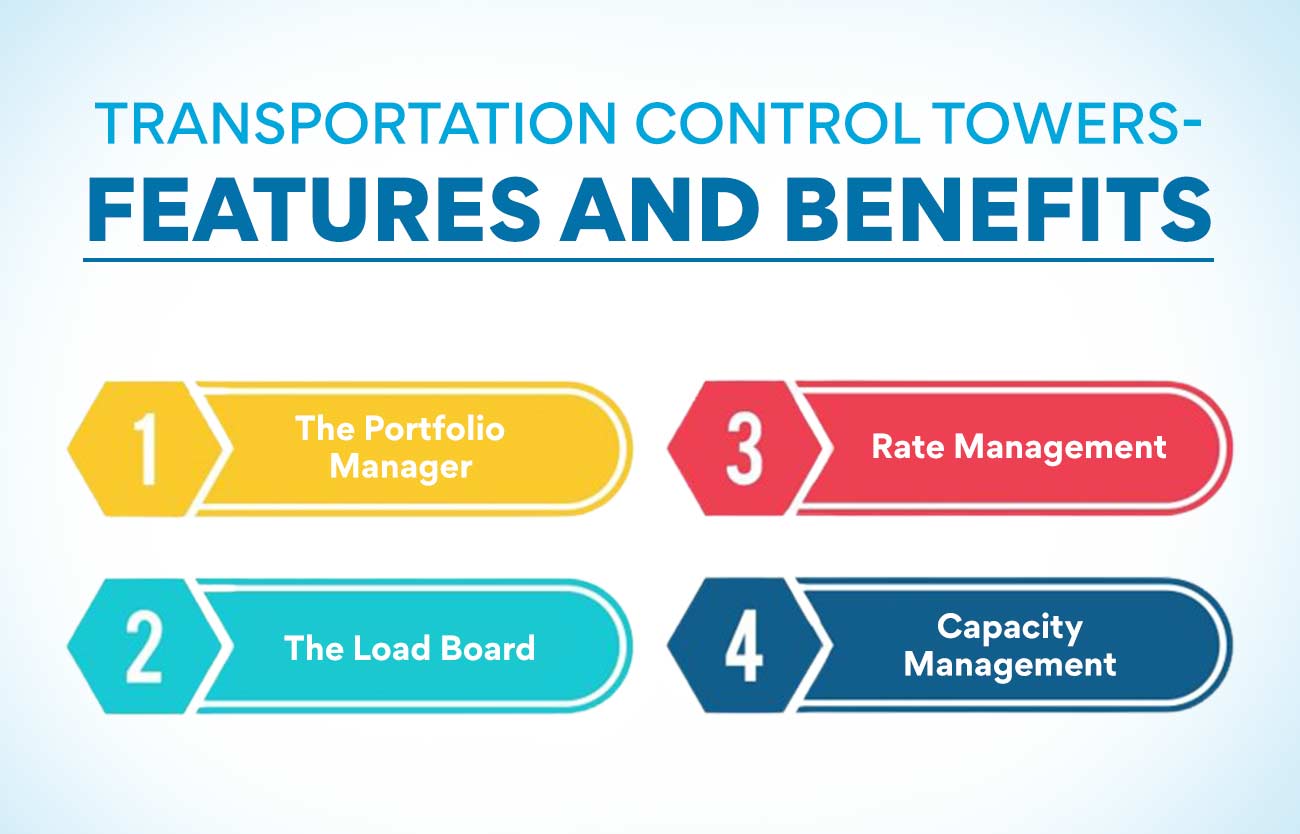

There are many different types of transportation control towers, each with its unique features and benefits. Here are a few examples:

- The Portfolio Manager: This control tower provides visibility into the entire transportation assets and resources portfolio. It helps organisations identify underutilised or underperforming assets and then makes recommendations on optimising them.

- The Load Board: This control tower provides visibility into loads transported by various carrier partners. It helps shippers identify capacity shortages or surpluses and then makes recommendations on optimising load planning and routing.

- Rate Management: This control tower provides visibility into current and historical freight rates. It helps organisations benchmark rates, understand trends, and then make recommendations on negotiating contracts with carrier partners.

- Capacity Management: This type of control tower provides visibility into the available capacity of carrier partners. It helps shippers identify capacity constraints and then makes recommendations on optimising the use of available capacity.

Analytical Control Towers – Explain with Examples

An analytical control tower is a centralised unit that uses data-driven analysis to optimise and manage the flow of goods and resources throughout the supply chain.

Analytical control towers are equipped with powerful data management and analysis tools that allow them to identify inefficiencies and bottlenecks, as well as opportunities for cost savings and improvements in quality and customer service.

By constantly monitoring the performance of the supply chain network, analytical control towers can proactively address issues before they cause disruptions. In addition, analytical control towers can provide real-time visibility into the status of shipments, inventory levels, and other critical metrics.

One example of how an analytical control tower can be used is to monitor supplier performance. The control tower can identify which suppliers are not meeting expectations by tracking key metrics such as on-time delivery rates and order accuracy. This information can then be used to work with those suppliers to improve their performance or find new suppliers who can better meet the needs of the company.

Another example is using an analytical control tower to optimise routes for shipments. The control tower can identify which routes are consistently causing delays or problems by analysing historical data. The information can then be used to plan alternative routes or make adjustments to current routes to avoid future disruptions.

Using an analytical control tower includes improved visibility into supply chain performance, proactive identification of issues, and improved decision-making. Analytical control towers offer a comprehensive view of the entire supply chain.

Also Read: Green Supply Chain Management: What It Is and Why It Matters?

Inventory Control Towers – Explain with Examples

Inventory control towers are supply chain control towers that focus on managing inventory. They use data and analytics to optimise stock levels and minimise the risk of stockouts.

There are many different types of inventory control towers, each with its strengths and weaknesses. The most common are:

- Centralised inventory control towers: These are typically used by large organisations with complex supply chains. They centralise all data and decision-making within a single team or department. This can lead to improved coordination and decision-making, but it can also be rigid and sluggish to respond to changes.

- Decentralised inventory control towers: These are typically used by smaller organisations or those with simpler supply chains. They decentralise data and decision-making, giving each team or department more autonomy. It can lead to faster decisions and more flexibility but can also be less coordinated and lead to the duplicated effort.

- Hybrid inventory control towers: These combine aspects of both centralised and decentralised models, giving the organisation the best of both worlds. However, they can also be more complex to set up and manage than either pure model.

The choice of which inventory control tower to use depends on the organisation’s specific needs. There is no one-size-fits-all solution – it depends on what will work best for your business.

Conclusion

A supply chain control tower is a centralised, real-time decision platform that orchestrates all the moving parts of a company’s supply chain. It allows organisations to monitor, manage and optimise their supply chains to improve efficiency, reduce costs and increase customer satisfaction.

The benefits of using a supply chain control tower are numerous. For one, it provides visibility into every component of the supply chain so that problems can be detected and corrected quickly. It also allows companies to respond promptly to changes in demand or other disruptions. Additionally, it can help companies make better inventory levels, production schedules and transportation routing decisions. Ultimately, a well-run control tower can lead to a more efficient and profitable business.

Want to start a career in supply chain management and ace the SCCT? We have an amazing course for you. Check out our Advanced Certificate in Operations, Supply Chain and Project Management.

More Information:

Roles and Functions of Operations Management

A Beginner’s Guide To Operations Management

What is the difference between logistics and supply chain management?