The supply chain is one of the crucial elements in a business. It includes sourcing, manufacturing, storage and delivery of goods. All these are crucial tasks that must be performed most efficiently. Difficulties arise because different people handle them and are not always connected. If the supply chain is inefficient, it could lead to increased costs and reduced profitability. Supply chain issues will also greatly affect customer experience, and this could lead to even losing them. The solution for this is supply chain optimisation.

What Is Supply Chain Optimisation?

Simply put, supply chain optimisation means making the supply chain perform at its peak efficiency. The aim is to deliver products to the customer at the lowest cost while ensuring that the company makes the highest profit. The method to meet this goal is for all supply chain officials to balance the cost of manufacturing, inventory, transportation, order fulfilment and customer service expectations. Key performance indicators like total operating expenses and gross margin returns on inventory are considered while calculating the efficiency of the supply chain.

Supply chain optimisation is not something that anyone can do quickly due to the complexities involved. Companies must be ready for a long process. Moreover, constant monitoring is required as many factors keep changing. The supply chain mix that provides the best profits and least cost can change depending on other factors. The cost of raw materials, transport charges and customer expectations can change over time. It can even be called a continuous process as changes need to be made as the various elements of the supply chain change.

Those aspiring to become supply chain managers must be familiar with this process and should know how it should be performed. The Advanced Certificate Course In Operations, Supply Chain and Project Management is the best place to learn about it. A visit to our website will help you with more information on the course.

Why Supply Chain Optimisation?

Companies usually go for supply chain optimisation due to various major events. This is done when there are concerns regarding the company’s financial performance. Sometimes it is also done when transportation charges are increasing, customer services are not satisfactory or when other components of the supply chain have complaints about the process. As companies scramble to meet changing customer expectations, supply chains have grown in an unplanned manner. The migration to direct sales due to increasing e-commerce business has also resulted in increased delivery costs. This also can lead to companies considering optimising their supply chains.

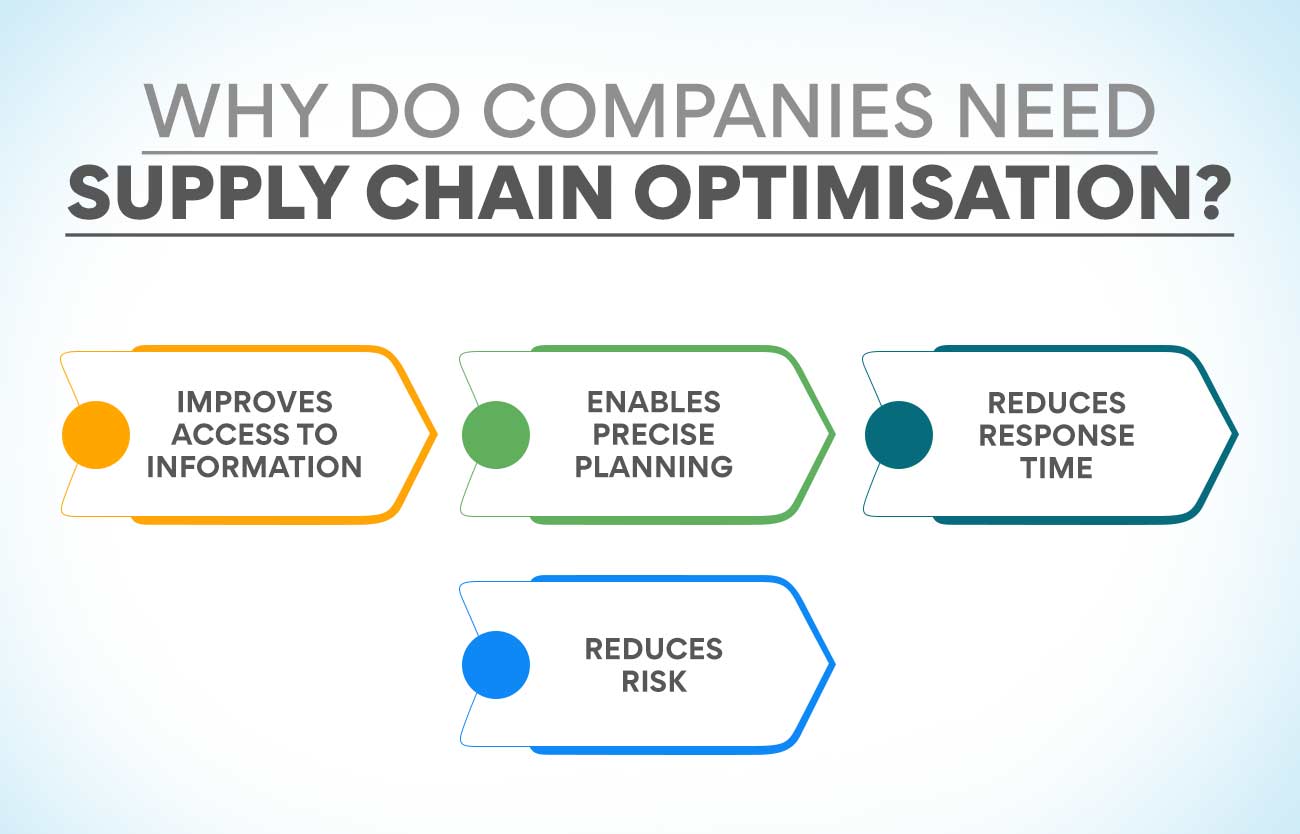

Why Do Companies Need Supply Chain Optimisation?

Before starting the process, it is essential to know why it is important for organisations to do this exercise. It is necessary to know what it will do to supply chain operations.

- Improves Access To Information

The supply chain is an operation that is spread across various departments. This can result in information being siloed in certain places and not being visible to everyone in the chain. Such a situation can reduce the effectiveness of the management and make the system more prone to issues. Once the optimisation is done, all the players in the chain will have access to information.

- Enables Precise Planning

Planning is highly essential for supply chains to work efficiently. Supply chain optimisation ensures that all information is shared with everyone. This helps in better planning for any event that can disrupt the system. It also helps the supply chain teams to do better production planning with correct demand forecasts. They can also prepare the budget accurately as all data is available.

- Reduces Response Time

Better visibility and planning help to avoid serious problems. With increased transparency, supply chain optimisation helps teams respond to unexpected events much faster. They can anticipate future events and take preventive measures.

- Reduces Risk

A supply chain is always filled with risks because of various unexpected events. Companies must strive to reduce risks that can cost money and disappoint customers. Optimising the system helps reduce dangers like production delays, supply chain disruptions, data leaks and failing delivery expectations.

Also Read: What Is The Scope Of Operations Management?

Key Supply Chain Optimisation Features

Though the features may differ with companies, you can find some in most optimisation processes.

Supply Chain Visibility – Optimising the supply chain will ensure that all stakeholders have good visibility of the process.

Order Management – A good supply chain will have tracking facilities, capturing, fulfilling, and managing orders to ensure maximum customer satisfaction.

Inventory Control – An optimised SCM will have advanced methods of tracking and maintaining inventory using modern technology. It helps maintain the optimum inventory.

Analysis & Reporting – Effective management and utilisation of historical and current data is another feature of supply chain optimisation.

Sustainability – Optimised supply chains have sustainability in end-to-end supply functions. This results in more customer loyalty.

One can learn more about this process in the Advanced Certificate Course In Operations, Supply Chain and Project Management. You can learn more about this program by visiting our website.

Goals Of Supply Chain Optimisation

Supply chains are different in different companies. Choosing the goals for optimisation can be difficult. The best way is to base your process on the company’s business and operation goals.

Inventory Optimisation

Inventory costs money, and every company must strive to maintain it optimally. But there are other reasons for inventory optimisation. While undertaking this exercise, the company can identify the fast and slow-moving items. It will help to decide which products must be stored in more accessible places. It can decide where the warehouses must be located. Inventory control also gives out highly valuable information for improving multiple business processes.

Improve Shipping And Order Fulfilment Time

Logistics is an important component of the supply chain. Optimising it will result in a reduction in shipping and order fulfilment time. Supply chain optimisation should focus on this goal because it is the way to achieve the organisation’s objectives. Achieving this goal will also mean better customer satisfaction. It will also greatly reduce shipping costs and increase revenues.

Improve Operational Efficiency

It is another way to ensure customer satisfaction and better sales. Optimising any one place in the supply chain will affect all operational aspects of the company. When the operations are more efficient, it will reduce the time taken for goods to reach the customer. It results in better customer satisfaction and loyalty.

Increase Revenue And Profits

Supply chain optimisation should focus on increasing revenues and profits. It can happen when you reduce waste in the supply chain. It means that there should be no product that doesn’t go to the market. Another way is to reduce the cost of delivery. One should look at ways to deliver more items with the same number of vehicles and drivers. Any reduction in the supply chain cost will automatically improve revenues and profits.

Reducing Cost

There are various ways in which companies can reduce costs along the supply chain. With so many components, it is one of the processes in an organisation that offer a lot of opportunities to reduce cost. Companies must look at reducing both fixed and variable costs. There is always a possibility of reducing warehouse rent. The optimisation should also focus on reducing other costs like raw material prices, transportation charges, etc.

Better Customer Service

Customer satisfaction is of utmost importance in a world with multiple suppliers for almost all goods. Companies must strive to keep customers happy by providing better service at every level. It is the end goal of any improvement in the supply chain. Reducing delivery time will be an excellent way to make a client happy, and the supply chain optimisation process must focus on this.

Ways To Achieve Supply Chain Optimisation

- Outsource Business Activities

Most organisations like to do all activities by themselves. But this is not always beneficial. Often, outsourcing some of the processes to companies dedicated to the activity can yield better results. It is possible to outsource many activities like procurement, logistics and customer service to other agencies. It can greatly reduce costs. It will help in optimising the supply chain process.

- Ensure Transparent Communication

It is a highly important aspect of supply chain optimisation. The organisation must make sure that there is transparent communication between it and the suppliers. It will help greatly in ensuring timely supplies of raw materials. Such free exchange of facts will also help in facing unexpected situations. Suppliers will also be willing to share information about price hikes and raw material shortages.

- Use Mobile And Internet Technology

Modern technologies help in communicating information. They can also be used to optimise the supply chain. Using mobile apps can help in tracking the movement of goods to the customers. Customers will also benefit from knowing when exactly they will receive the items. Social media is an excellent place to know the latest trends in customer preferences. This will help to judge any sudden surge in demand for a product.

- Use Centralised Management Systems

If the supply chain has to work efficiently, the various departments associated with it must be able to work together efficiently. Using software that helps to manage all the departments from one place can help in better coordination. Having an overall view of the supply chain will help in knowing if there is any obstacle anywhere. Such software programmes can help in completing the supply chain optimisation process successfully.

- Use A Multichannel Approach

Order fulfilment is critical in any business. This is especially true for eCommerce businesses. Requirements must be communicated to the suppliers on time to ensure that customers get their goods promptly. Using a multichannel approach helps in forecasting trends and planning the inventory. This will ensure prompt execution of orders resulting in customer satisfaction.

Also Read: How to formulate Advanced Supply Chain Strategy?

- Understand Suppliers

Supply chain optimisation depends greatly on sourcing at affordable rates. But one must also ensure that the raw materials or goods are of the best quality. This is possible only if you understand your suppliers and know their strengths and weaknesses. It will help in sourcing from the right vendor for different orders. The company must keep looking for suppliers who will sell good quality products at reasonable rates.

- Good Planning

Good planning is key to ensuring prompt supplies without extra costs. If there is good planning, even urgent orders can be executed without paying anything extra. If the inventory is planned well and stored at warehouses close to your customers, it is possible to supply goods within a short period without incurring more expenses. Good planning will also ensure that all the raw materials are in place to execute orders on time.

- Know Customer Trends

Knowing the customer and their purchase trends is crucial for optimising the supply chain. Companies must know the purchase pattern of their customers so that they can maintain an optimum inventory at any time. This will ensure that there is no extra cost incurred for overstocking. Analysing the sales data is the best way to make sure that enough goods are available to fulfil any order.

- Use Analytics Tools

Data analytics is an excellent way to understand sales trends. Knowing your customers’ requirements in advance helps you keep the items ready. It will also help in avoiding slow-moving stocking of goods. Companies can also find out the optimum stock level for each product using analytics tools. It will also help to find the shortest route to your customers, thus saving transport costs.

- Negotiate Regularly

The ultimate aim of supply chain optimisation is to improve revenues and reduce costs. The company must negotiate with its suppliers to get the best price. This will reduce the cost of inventory and result in better profits. But negotiation is not a one-time job. The sourcing team must know the latest market price of raw materials and regularly negotiate to get the best price.

Benefits Of Supply Chain Optimisation

Cost Reduction

With supply chain optimisation, a lot of unnecessary expenses can be avoided. Companies can either eliminate or automate repetitive or ineffective processes. Optimising inventory will lead to lower expenses. By improving the warehouse capabilities, delivery process and logistics, companies can reduce infrastructure expenses.

Improved Revenues And Profits

When the supply chain functions more efficiently, there is certainly better customer satisfaction. Orders will be delivered on time. The firm will be able to respond to customer demands quickly. This will improve customer experience, which can result in repeat purchases and word-of-mouth propaganda. As a result, the organisation gets additional sales at no extra cost.

Better Supplier Performance

Analytics is part of the supply chain optimisation process. This gives more insights into supplier performance. Wherever supplier performance is deficient, the firm can set it right quickly. Suppliers can also be rewarded for improving their working methods. When the relationship with the suppliers improves, the company will benefit from getting advanced information on various matters. This helps in making better sourcing decisions.

Better Supply Chain Collaboration

A supply chain consists of various partners both inside and outside the company. Optimising the supply chain ensures that information is shared with all these entities on a real-time basis. This leads to better collaboration between the various components. The company can make smarter decisions and avoid risks.

Integrated Supply Chain Management

Supply chain optimisation results in the visibility of all activities in a central point. Companies can gather a lot of insights into various aspects of the supply chain. Because of complete visibility, it is easy to make sales forecasts, manage cash flow, understand customer loyalty and ensure timely delivery. Because of the availability of all data to every element in the chain, there is complete transparency in operations.

The Advanced Certificate Course In Operations, Supply Chain And Project Management teaches much more about how a company benefits by optimising the supply chain. You can visit our website to learn more about this program.

Supply Chain Optimisation Techniques

- Cost Optimisation – The company looks at every area in the supply chain involving cost to see where reduction is possible. It brings about both short-term and long-term changes to achieve this.

- Inventory Optimisation – In this method, the team looks at all areas where inventory can be optimised to ensure customer satisfaction. Companies use analytics to find out supply-demand uncertainties and the solutions to overcome them. With this technique, the organisation arrives at the least inventory that needs to be maintained across the supply chain.

- Network Optimisation – Companies must know how each entity in the chain will react to changes. This method helps the organisation to the current supply chain system to many hypothetical situations and see how it will react. Based on these findings, the firm can make plans to ensure reduced cost and risk during these changes.

Conclusion

The supply chain is a critical function in every organisation. If it doesn’t perform well, the company can suffer great losses. There can be increased costs and loss of customer loyalty. To avoid this, the supply chain must perform at its best. Supply chain optimisation is the way to ensure that the firm gets the best out of its supply chain. Every aspiring supply chain professional must know how to complete the process successfully.

More Information:

What is Green Supply Chain? An Overview

Green Supply Chain Management: What It Is and Why It Matters?

What Is A Supply Chain Control Tower? Types & Uses

What is supply chain analytics? Importance, usage & examples