Management is an activity where the company achieves its goals using the available resources, including people. There are various departments in a firm, and all of them need to be managed to get work done efficiently. Some of the management activities overlap but yet maintain their roles and responsibilities. Production and operations management can be said to be like that. But yet they are not the same. Those who like to become managers in an organisation must know the difference between production and operations management.

We need to see each of them in detail before we understand the differences. The Advanced Certificate Course in Operations, Supply Chain and Project Management is the best place to understand these two jobs. You can visit our website to learn more about this course.

What Is Production?

Production is an activity where various inputs are processed to make a finished product. It is defined as a process where one form of material or materials are converted into another to improve their utility to the user. Various forms of production happen, either using chemicals or machines to convert the items. The function happens with different levels of complexity depending on the product. The management of such an activity is called production management. Before we see the difference between production and operations management, it is best to know what product management is.

Understanding Production Management

Production management is defined as the application of management principles to the conversion of raw materials to finished goods. It involves planning, scheduling, supervising and controlling the activities of men and machines involved in the process. While the manufacture of goods was done in small shops earlier, now they have expanded and become large factories that need efficient management to complete it efficiently. There are too many components involved in a production that only with proper supervision and control can it be done profitably. Production management also ensures that the product’s quality is as per customer requirements.

Also Read: How To Become A Better Product Manager: Top 10 Tips

The purchase and maintenance of machines also come under production management. This team also decides the design and packaging of the product based on inputs from the marketing and sales teams. The production team also decides the location and layout of the manufacturing units to reduce costs and improve efficiency. Production managers are also responsible for scheduling production to ensure that goods reach the customer on time. They also are tasked with ensuring that the quality of goods produced is as per the standards decided by the management.

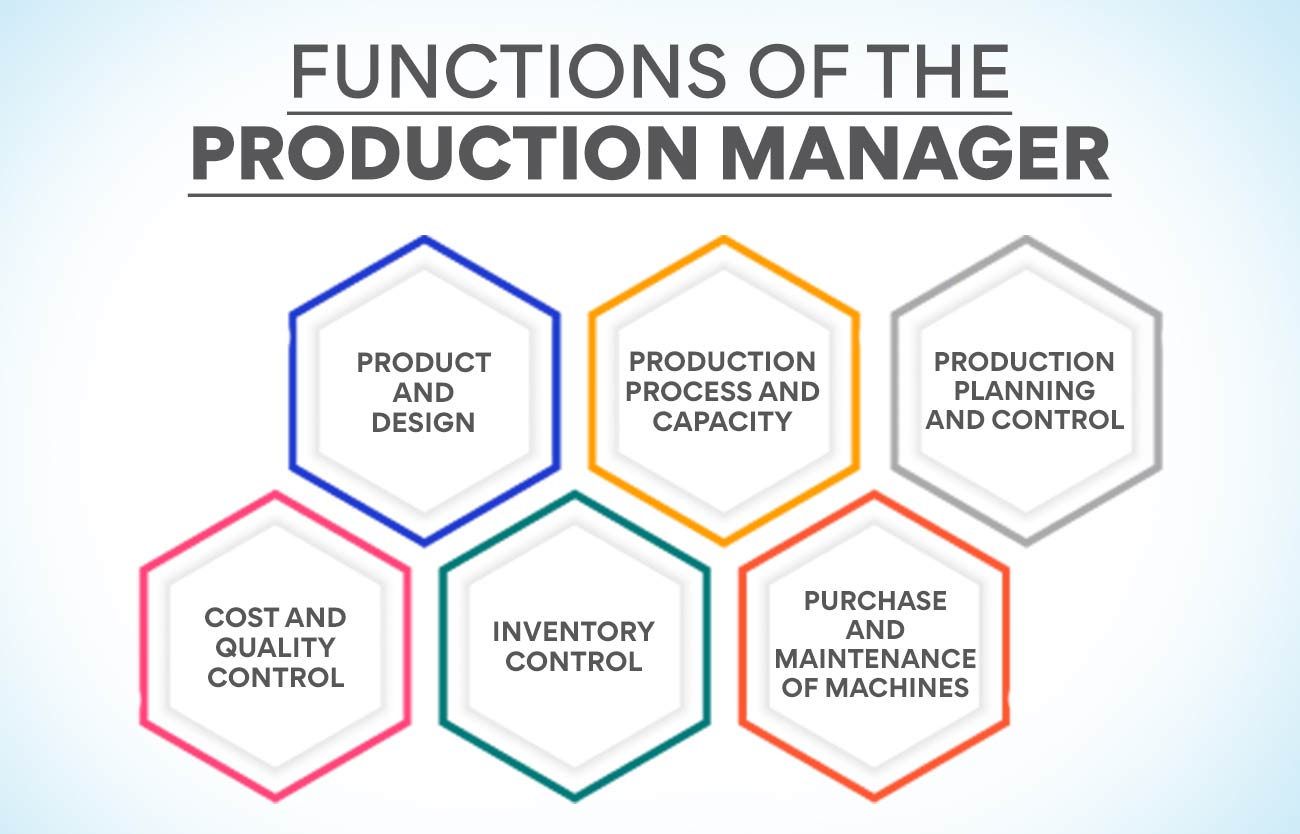

If we should understand the difference between production and operations management, we must first know the functions of both managers. Let us see the functions of the production manager.

Functions Of The Production Manager

- Product And Design

The production manager selects the right product for the market first. This is followed by selecting the design for the product. Both these are decided to keep in mind the requirements of the customer. The company’s survival depends on choosing the right product and design to satisfy customer needs and earn profits for the organisation. The production management must also ensure that the product gives the maximum value to the customer at the lowest price. The team must use value engineering and analysis techniques to arrive at the best product and design.

- Production Process And Capacity

Production management includes deciding the process and capacity. Finding the best process that can result in the desired product is necessary. Production managers decide the machines, technology and material handling system. They must also decide what capacity the manufacturing unit must have to ensure the availability of products to satisfy customer requirements. Having a higher or lower capacity can result in the inability of the organisation to achieve its goals. The team must also have both long-term and short-term production capacity planning.

- Production Planning And Control

Production planning includes two main tasks – routing and scheduling. Routing means the path of work and the sequence of operations. The aim is to arrive at the best and most economical flow of tasks to achieve the desired result. It ensures a smooth flow of work without any disruption. Scheduling is the decision of when to start and stop production. Production control is done to ensure the process is progressing as planned. If there are any deviations, the PM takes necessary action to correct them.

- Cost And Quality Control

While understanding the difference between production and operations management, it is important to know what cost and quality control are. The production manager’s responsibility is to ensure that the product conforms to the quality that the company has set for the item. It is important to ensure customer satisfaction and survival in a competitive market. Price is another crucial factor in the market. Controlling the cost of production is necessary to ensure that the product price remains low enough to compete with other products.

- Inventory Control

This is another function that will ensure customer satisfaction and cost reduction. The production manager must make sure that there is an optimal inventory of both raw materials and finished goods. Having a low inventory can result in the non-availability of the product to meet market demands. It will result in customers opting to buy the competitors’ products. Overstocking will lead to unnecessary expenses. This can greatly affect the profitability of the company. The production manager will take the help of people in the stores and modern applications to ensure the maintenance of optimum stocks.

- Purchase And Maintenance Of Machines

The machines that are used for production must function to their optimum capacity if the company must get the best yield. But they are likely to develop problems or work below their capacity after some time. Companies must maintain them well to utilise them to their full capacity. Checking them regularly and doing the necessary repairs come under the responsibility of the production managers. They must also plan well ahead for replacing equipment that cannot perform well. The production managers must also keep themselves updated with the latest upgrades of the machines.

Now that we have seen the functions of a production manager, it is time to learn about operations management. That is how we can understand the difference between production and operations management. The Advanced Certificate Course In Operations, Supply Chain and Project Management is the best program to learn about the function. A visit to our website will enlighten you about the course.

What Is Operations Management?

There is a very small difference between production and operations management, so much so that earlier, this function was also known as production management. However, operations management is a broader function, including all activities of the organisation. It ensures that the firm runs smoothly and delivers what is desired by the management. This function includes both production and non-production activities. The main objective of operations management is to make sure that the company’s resources are used optimally and waste is brought down to the minimum possible level.

Operations management is crucial for ensuring that the company improves its overall efficiency. It creates a strategy to maximise resources in the company and to secure a prominent position in the market it operates. Effective operations management can also help in improving the financial position of the company. Along with the production team, it works towards creating products that can earn good profits and satisfy customer needs. It takes into consideration possible changes in the market conditions and plans future courses of action for the firm.

Functions Of Operations Manager

- Operations Planning

This is the foremost job of an operations manager. It includes keeping track of the daily production of goods. The operations manager must also keep a sharp eye on the inventory to ensure that it stays at optimum levels. Keeping a tab on the performance of the team members and ensuring that they have everything that is needed to perform their jobs also comes under the purview of operations planning. They must ensure operational efficiency and be on the look for new technology that can improve the company’s profits.

- Financial Management

The operations manager must also manage the finances related to the production and daily activities of the company. Creating budgets to meet production targets and allocating the money for this is also part of operations management. The operations team must also manage resources and ensure their optimum use to reduce waste. Good financial planning on the part of the operations team ensures cost reduction and an increase in profits.

- Demand Forecasting

This is an important function, and this is where you can see the difference between production and operations management. Demand forecasting is the responsibility of operations management. Only with an accurate prediction of future demand can they plan production. The information from the market is very important for this. This is an area where data-driven decisions play a major role. The use of analytics in forecasting is very important, and operations managers need to be familiar with this technology. They must be able to use data to forecast future demand and plan production accordingly.

Also Read: What Are The Stages And Examples Of A Product Lifecycle?

- Strategic Planning

The operations manager must plan carefully to ensure that the company objectives are met. The decisions of the production and operations team must match the goals of the organisation. Most firms work towards improving customer satisfaction, reducing costs and increasing profits. Operations management teams should focus on maintaining optimum inventory to reduce costs. They must also ensure that product quality and delivery are maintained to meet customer expectations. Operations managers must strive for collaboration among teams to ensure efficient working.

- Supply Chain Management

The supply chain is a critical operation in every organisation. It involves a lot of departments and people, and hence its efficiency depends on proper coordination and sharing of information. Those functions of the supply chain within the company come under the control of operations management. The operations managers need not perform all the functions but must plan and strategies to ensure that goods are delivered on time and that there is enough in stock to meet market demands. They must also make sure that all teams in the supply chain collaborate to make it more efficient.

What Is The Difference Between Production And Operations Management?

Now that we have seen both sections separately, it is time to look at how they differ from each other.

- Definition

Production Management is concerned with the conversion of raw materials to finished goods

and the maintenance of machinery for this purpose. This function also involves product design and production planning.

Operations management deals with both production of goods and other activities like the provision of services to customers. The job also concerns with the usage of resources and ensuring the execution of daily activities.

- Functions

The production manager has to ensure the timely production of goods as per the requirement of the market. The person must also plan the production in such a way that there is never a shortage or excess of goods. Stringent quality control is also the job of the production manager.

Operations managers must look after production apart from various other jobs. They must ensure that the manpower required for producing the items is available. They are also responsible for forecasting demand and making the necessary materials available for production. Inventory management, logistics and waste management also come under operations management.

- Existence

Production management can be found only in companies that manufacture products.

Operations managers exist in all companies, even those that don’t manufacture anything. These officials are necessary for the functioning of all organisations to ensure the optimum use of the available resources.

- Objectives

The objective of the production management team is to provide a product with high quality and low prices in the right quantity and at the right time.

The operations management team aims to make optimum use of the company’s resources to ensure smooth running, reduced costs, customer satisfaction and increased profits.

Those interested in knowing more about these functions can join the Advanced Certificate Course in Operations, Supply Chain and Project Management. Our website provides more information about the course.

Conclusion

The responsibilities of operations and production management may look similar, but there certainly are different functions for both. Understanding the difference between production and operations management helps you appreciate the capabilities of those handling the jobs. Both have their challenges, and attending a course in the subject from a reputed institution will help you perform the tasks efficiently.

More Information:

7 Dynamic Stages of the New-Age Product Development Process

What is Operations and Supply Chain Management (OSCM)?

What is the difference between logistics and supply chain management?